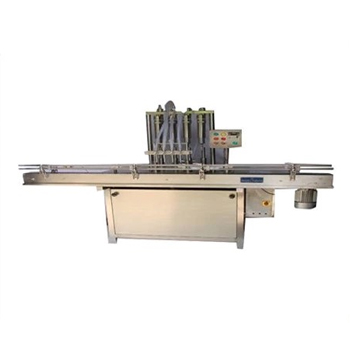

Powder Bottle Filling Machine Manufacturer & Supplier

Setting the Standard for High-Volume Powder Accuracy

The Powder Bottle Filling Machine forms the basis of high-volume filling of nutritional supplements, pharmaceuticals, and household powders. This automated system is designed to operate 24/7 and is designed to eliminate the weight variances and labor expenses of the manual dispensing system. Being a type of specialized powder bottle filling equipment producer.

Nextgen Packaging Solution incorporates control systems that are highly sophisticated to provide the required precision of the repeatable process of filling needed to sustain regulatory compliance and profitability to the maximum in each bottle.