Detailed Product Portfolio: Engineered for Every Need

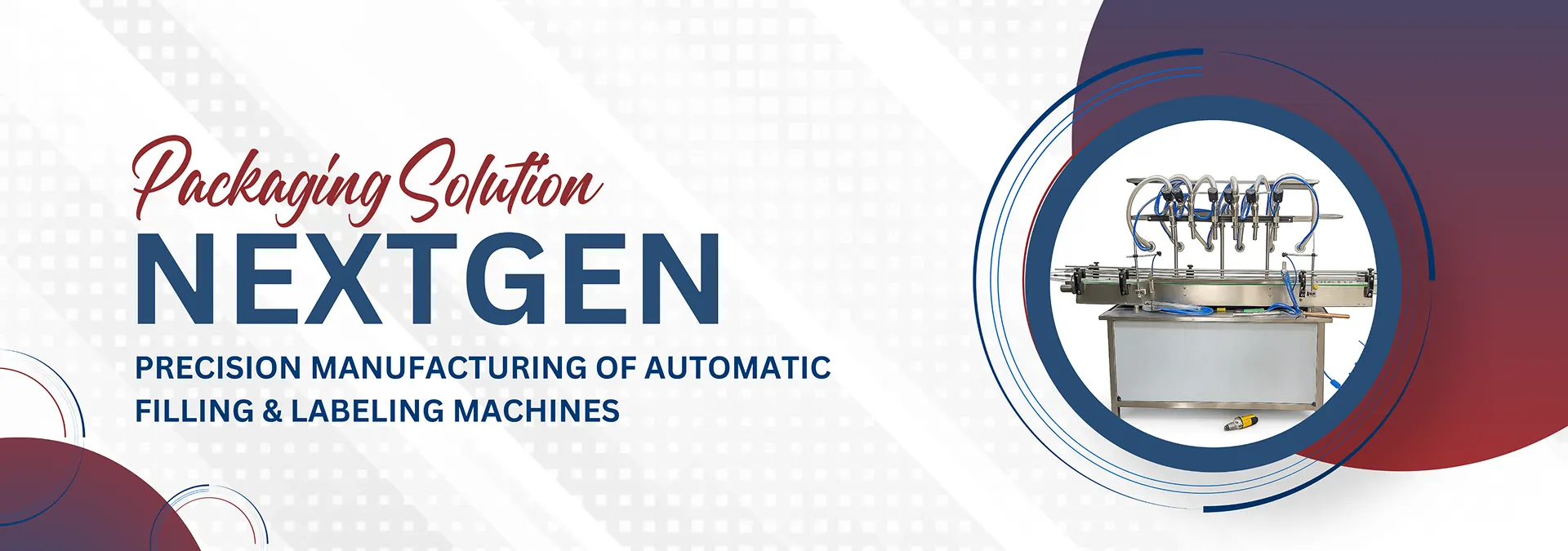

1. Advanced Liquid Filling Machines (The Core of Our Expertise)

Our machine fills any kind of liquid, from thin solvents to high-viscosity creams and oils, without any drip.

- Automatic Servo Volumetric Liquid Filling Machine: Installs servo motors to ensure a precise movement of the piston, which ensures that the filling is accurate to at least 1 percent and up to 120 Bottles Per Minute (BPM). Optimal with pharmaceuticals and high-value products.

- Automatic Liquid Bottle Filling Line: Fully integrated system with bottle cleaning system, bottle filling system, inner plugging system, and capping system.

- Specialized Fillers: Incorporates the Automatic Edible Oil Filling Machine (volumetric sensors or net weight sensors) and the Automatic Shampoo Filling Machine (designed to use highly viscous products).

- Volumetric 4 Head/6 Head Filling Machines: Fast solutions of general liquids and beverages.